- Sign In

- |

- Sign Up

- |

- My Quote (0)

- |

- CART (0)

How to Effectively Protect and Maintain Wind Turbines

Written by: Global Test Supply,

Ensure your wind power systems are properly and reliably maintained to protect them from lightning strikes

Figure 1: Wind turbines in action on the coast

Renewable energy practices, specifically, wind power systems, are rapidly growing and becoming more common. It is relatively inexpensive and is a green energy source that addresses constrained budgets and ever-changing climate change policies. These positive aspects mean electrical power industries will experience continued growth and opportunities for years. Notably, a vital component of a wind power system is wind turbines, which use the wind to make electricity.

A reliable power system depends on regular maintenance and comprehensive protection against harsh environmental conditions and electrical transients.

However, while there are many positives, it is necessary to remember that this growth requires improved maintenance programs to protect investments and maximize profits. For this reason, a reliable power system depends on regular maintenance and comprehensive protection against harsh environmental conditions and electrical transients.

For instance, one of wind turbines' most significant and common concerns is lightning strikes due to their height and location. Moreover, lightning faults cause more loss in wind turbine availability and production than average faults. With this in mind, operators and owners must ensure they have an extensive lighting protection system, plus a comprehensive and effective maintenance program.

Figures 2a and 2b: Damage from lightning strikes on wind turbines

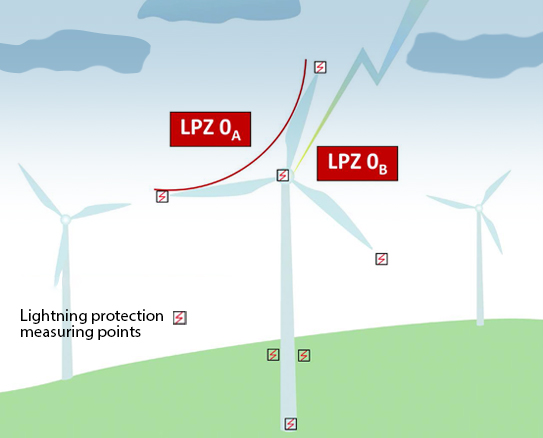

Foremost, a lightning system is essential in ensuring wind turbines are adequately protected from lightning strikes. A lightning protection system (LPS) directs the current strikes to the ground, which essentially works by taking the form of a low-resistance path toward the ground. The lightning path travels from the blade tip to the turbine base, so in the event of a lightning strike, the current will flow to the ground through the LPS and not touch the sensitive equipment. Additionally, it is prudent to divide the wind turbine into lightning protection zones (LPZ), a structured measure for creating a defined, electromagnetically compatible environment in an object, keeping in mind the object's stress withstand capability. Lightning protection zones are classified as either internal or external, depending on their exposure to direct lightning.

External zones

LPZ 0A zone is where the threat is due to the direct lightning flash and the whole electromagnetic field. Internal systems may be subject to lightning surge currents.

LPZ 0B zone is protected against direct lightning flashes, but where the threat is the whole lightning electromagnetic field. Internal systems may be subject to partial lightning surge currents.

Internal zones

LPZ 1 zone is where the surge current is limited by current sharing and isolating interfaces or by surge protection devices (SPD) at the boundary. Spatial shielding may attenuate the lightning electromagnetic field.

LPZ 2 to LPZ n zones are where the surge current may be further limited by current sharing and isolating interfaces or additional SPDs at the boundary. More spatial shielding may be used to attenuate the lightning electromagnetic field.

Figure 3: Simplified wind turbine external LPZ

To ensure protection in the above zones will work when needed, regular measuring of the resistance of the lightning path is crucial, and this is possible with a low-resistance ohmmeter. Low resistance measurement is affected by fundamental factors, including measurement type, testing of the current magnitude, length of measurement leads, and place of leads/probes. The most appropriate measurement method is the four-wire method because it uses separate current probes to inject direct current and other probes to measure the voltage drop across the test specimen. Furthermore, it is vital to utilize the proper range and test current magnitude because the length of measurement leads must accommodate the span of the blades. Similarly, routine and extensive maintenance programs ensure wind systems are optimal.

Regular maintenance and inspection are key in wind power.

Regular maintenance and inspection are crucial to keeping wind turbines running. Each component of the turbine, like the propeller-like blades and generator, is essential to creating electricity, so if one of these segments fails, the turbine will not work. By regularly performing the following tests, the wind turbine will continue to work effectively and efficiently for years.

1. Electric motor and generator testing

A properly functioning generator is fundamental in creating power with wind turbines. If the generator is malfunctioning, it may overheat or stop working. That is why static motor testers should be in use to perform routine tests and to determine if there is moisture or other contaminants in the generator that may be of concern.

2. Contact resistance testing

Busbar, cable joints, and high-voltage circuit breakers in or near the tower need testing to eliminate potential hazards caused by induced voltages. Contact resistance testing of circuit breakers is a crucial safety test, and poor contact resistance leads to poor circuit breaker performance can lead to electrical damage. Circuit breakers are vital safety devices that ensure disconnection in the event of a fault. Therefore, in locations where the power supply is limited, a high-current micro-ohmmeter is best for it can conduct a full day's worth of testing.

Figure 4: Ground resistance tester with test leads

Ground resistance testing helps prevent rises in voltage caused by a fault current, surges, and lightning strikes in earth/ground systems.

3. Insulation resistance testing

Testing the insulation resistance of high-voltage power cables and buses, large motor/generator windings, and transformers is extremely important to ensure the integrity of the generator's winding insulation and the likelihood of developing a ground. As a result, micro-ohmmeters are the best option to perform these tests while ensuring the highest accuracy possible.

4. Earth/ground resistance testing

Ground resistance testing helps prevent rises in voltage caused by a fault current, surges, and lightning strikes in earth/ground systems. To ensure turbine cables can deal with these sudden voltage increases, use an earth/ground digital clamp-on resistance tester, which allows for the easy access and testing of cables found in wind turbines as it can clamp around the cable and measure ground resistance. Measuring the ground resistance of turbines under IEEE 81 standards requires test reels with resistance testers. Measure the Fall of Potential value with this diagnostic tool when problems arise with the wind turbine, and use it to test grounding and lightning protection.

5. Low resistance testing

Measuring low resistance helps identify components where resistance exceeds acceptable values. Lightning strikes can cause a great deal of downtime and power loss for wind turbines, and as towers become taller, the number of strikes increases. Several spots on a wind turbine, like the weather mast, roof cooler, control panels, nacelle-tower junction, nacelle-hub junction, and machine support, require testing using ohmmeters and test leads to ensure low resistance.

Ultimately, lightning strikes are an immense threat to wind turbines, and as wind power systems continue to expand, the requirement to protect these assets is essential. Finally, owners and operators must ensure that the installation and maintenance of turbines are routine and effective, so it is vital to establish a reliable system.

JUMP TO...

The use of these instruments for this application is paramount, our team of experts are trained and ready to answer your questions.